Solutions

Hydrogen

Pioneers of hydrogen compression since 1996. Reliability, power, vision.

Since 1996, we have been developing hydrogen compression solutions. From production to distribution, our systems guarantee high performance, safety and modularity. We power strategic projects around the world, supporting the energy transition with proprietary technology and engineering know-how.

Solutions

Biomethane

Compression tailored to each system. Efficiency, modularity, value over time

We develop flexible, compact and highly efficient biomethane compression systems. From agricultural plants to industrial sites, we support every configuration with customized, robust and easy-to-integrate solutions. We guarantee operational continuity, maximum energy efficiency and a significant reduction in management costs throughout the entire life cycle.

Solutions

CNG

Reliability, performance and compactness for natural gas compression

With over 50 years of experience in natural gas compression, we offer reliable, safe and customizable CNG solutions. Ideal for fueling stations, corporate fleets and public transport, our systems guarantee high performance, easy maintenance and continuous operation even in critical conditions.

Solutions

Oil & Gas

Robust and tailored technologies for onshore, offshore and midstream applications

We design high-performance compression systems for every segment of the Oil & Gas industry. Our solutions cover all phases — extraction, transportation and treatment — and are distinguished by reliability, safety and the ability to operate in extreme environments. Tailor-made engineering, advanced technology and continuous support for your strategic plants

Solutions

Industrial applications

Versatile and reliable technology for industry. Compression at the service of your processes

From distribution networks to production processes, SAFE develops high-performance compression solutions for complex industrial applications. Our systems are designed to ensure continuity, safety and efficiency in sectors such as gas treatment, power generation, chemical and manufacturing. We support customers with customized engineering, ongoing support and a complete range of integrated accessories

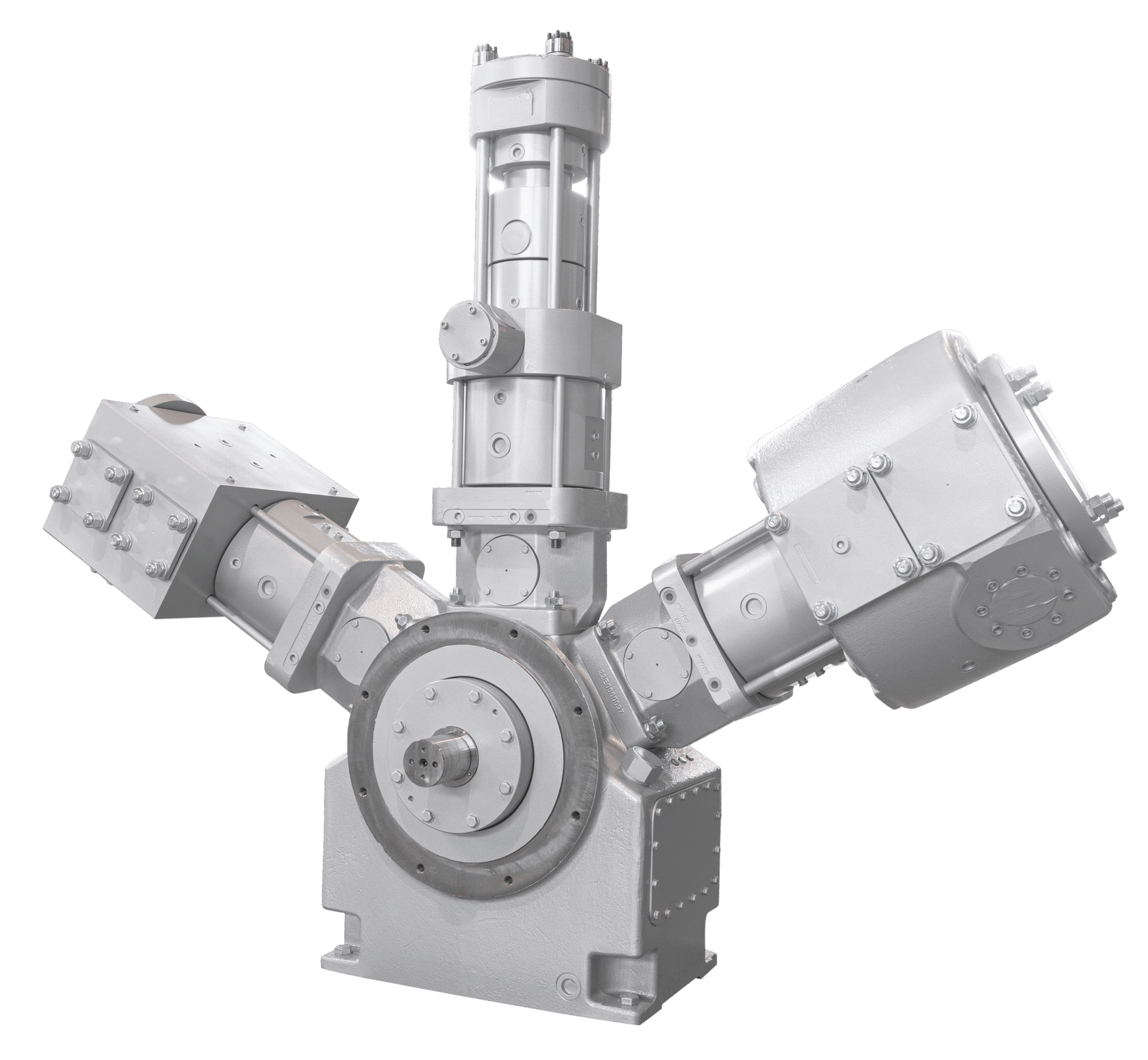

SW/H₂ Series compressors are the largest mechanical units produced by SAFE. Equipped with 2 or 3 cylinders arranged at 60°, they are designed for:

- Applications requiring hydrogen compression at low suction pressures

- Hydrogen fueling systems for automotive

- Storage Solutions and Hydrogen Virtual Pipeline

With OIL-FREE configuration as standard, SW/H₂ compressors ensure operational efficiency, maximum safety of the compressed gas and very low leakage levels.

Integrated

Solutions

From need to solution, without interruptions

We listen to the customer’s needs, translate them into concrete technical solutions and implement them internally, guaranteeing efficiency, reliability and speed of execution.

Our integrated solutions — such as mobile stations, compact units, prefabricated systems — represent the most advanced expression of this customized approach, where each component works in synergy.

The conversion of 200,000 tons of agricultural waste per year produces biomethane, compost, fertilizer and reusable CO₂, reducing emissions. Thanks to SAFE technology, biomethane powers approximately 12,000 homes with an integrated and efficient process.

Find out more

The CNR has created the first hydrogen station for school buses in Italy, eliminating emissions thanks to solar panels that produce clean energy. The SAFE solution, compact and efficient, includes an electrolyzer, compressor, storage and dispenser, guaranteeing pure hydrogen without contamination and low energy consumption.

Find out more

Compressed natural gas (CNG) is an environmentally friendly and cost-effective alternative to traditional fuels, especially for heavy-duty vehicles. In the UK, the use of CNG has reduced CO₂ emissions by 84% and costs by over 40%.

Find out more

Monitoring

SAFE offers a remote monitoring system that allows real-time diagnostics of all plant parameters. The connection is via a protected internet network, with rapid and secure access to key information to ensure operational continuity and timely interventions.

Training

Technical training is an integral part of the SAFE experience. We offer multi-level structured courses to transfer fundamental knowledge on natural gas, compression, and facilities management, with practical focus and real-world cases.

First Level

Local technical assistance, with trained teams and dedicated spare parts warehouse. Timely interventions for ordinary and scheduled maintenance, in full compliance with safety and reliability standards.

Second Level

Advanced technical support from our central specialists. In-depth diagnostics, performance analysis and strategic spare parts management for complex or recurring interventions.

Third Level

Applied engineering and customization: plant optimization, technological upgrades, retrofits and development of customized solutions in direct collaboration with the SAFE R&D team.

Fill out the form selecting the level of assistance required. Our team will contact you to offer the solution best suited to your operational needs.

Lorem ipsum dolor sit amet consectetur. Enim vestibulum aliquet dignissim ipsum faucibus. Gravida in ac egestas semper mauris condimentum. Senectus faucibus sit vel interdum ultricies ultricies tincidunt.