Virtual Pipeline Biomethane

Solution

Country

Europe

Italy

The recovery and valorization of the organic fraction of municipal solid waste (FORSU) or “Source Separated Organics” (SSO) through conversion generates environmental and economic benefits.

Biomethane is obtained from the purification of biogas from which, through a filtration system, contaminants and CO2 are removed, resulting in biomethane with purities greater than 99%.

The management and valorization of continuous biomethane production requires access to distribution infrastructure (gas grids), which, depending on the geographic area or country, may not be available.

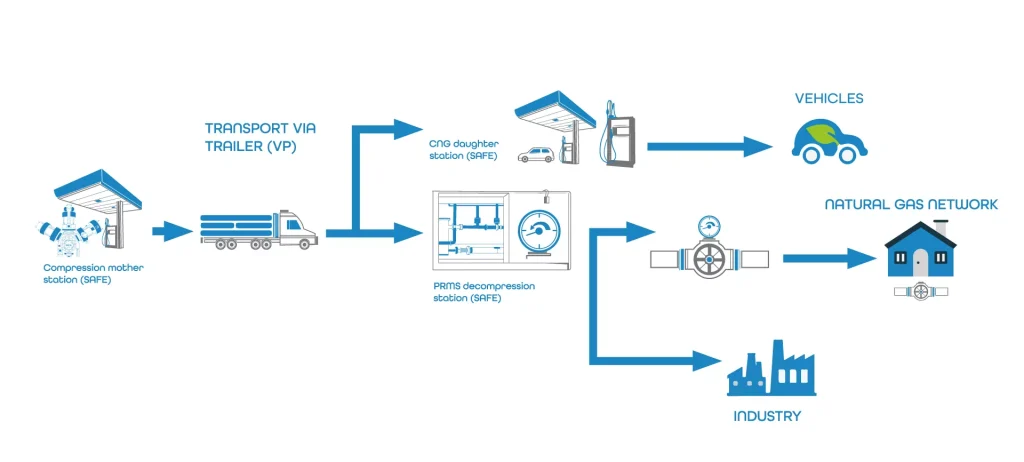

In such circumstances, a widely used solution is the so-called Virtual Pipelines: gas (in this case biomethane) is transported in the form of high-pressure compressed gas via tank cars between the production site and the distribution site.

Final valorization is by grid injection, sale to the public, or refueling of fleets.

Tank wagon loading station (mother)

Capacity of 1500Sm3/h with single compressor and large adjustment capacity according to biomethane flow rate. Two-point charge dispensing system.

Station charge fleet (daughter)

Capacity of 1500Sm3/h with single compressor and large adjustment capacity for complete emptying of the tank wagon. Dispensing system on two vehicle charging points.

Turn-key solution

Compressor and charging stations complete with metal cabinet and installation with supply of interconnecting piping.

SAFE provided the turnkey solution for the compression and delivery of biomethane along the entire Virtual Pipeline value chain. Specifically, the following were provided:

- Mother station deputed to charge the tank cars to the production site;

- Daughter station for loading private fleet vehicles at the distribution site.

The example has particular relevance from a technical point of view since, thanks to its experience in biomethane and CNG, SAFE was able to present itself as a “one shop stop” partner for turnkey solutions of compression and distribution technology.

In addition, the project has considerable relevance from a sustainability point of view as it creates the basis for a circular economy: biomethane-powered vehicles carry out separate collection of FORSU, which is in turn transformed into biomethane and, via the Virtual Pipeline, dispatched to the charging station (daughter) where the separate collection vehicles are refueled.

Read more

Wagon loading station:

In addition to compression and delivery technology, the solution provided also presents the installation of the systems and the construction of the interconnecting piping between them.

SAFE provided a soundproof and weatherproof Microbox M6 module inside which a SW compressor was installed with direct coupling to the electric motor in addition to the control panel compartment made in a safe area. This is a complete compression module for charging biomethane tankers that allows flexible management of gas flow in addition to integration as a module within the biomethane production system.

The compression system consists of a SW compressor capable of compressing gas from 15 barG 220 barG reaching a maximum flow rate of 1500Sm3/hour. The flow adjustment range (0%-100%) is achieved by VFD and recirculation line.

The station is complemented by two wagon charging lines fully integrated into the station design and installed in the charging tunnels.

Media charging station:

SAFE provided a charging station consisting of a soundproof and weatherproof Microbox M4 module inside which an electrically powered hydraulic compressor was installed in addition to the control panel compartment made in a safe area. The charging station has been provided with a tank wagon connection system that allows gas to flow from the tank wagon to the station and finally to the dispensing terminal. Complete compression module for fleet charging of trucks with biomethane taken from tank wagons that allows flexible management of complete emptying of tank wagons while ensuring the necessary charging speed.

The compressor system consists of a hydraulic compressor capable of compressing gas with a wide range of suction pressures from 25 barG to 200 barG ensuring rapid recharging of the vehicles regardless of the charge level of the tank wagon. The station dispensing system consists of a two-connection dispenser with a two-line priority panel that allows simultaneous charging of two vehicles.

Gallery /